Graphene yarns facilitate energy storage textiles

Unless you want to strap a battery pack on your belt, the flexible and textile-embedded electronics of the future will require an equally flexible and embedded energy supply. To realize devices like electronics on gloves (read more: "Nanotechnology electronics at the tip of your gloved finger") or displays integrated into your shirt sleeves, equally flexible power sources need to be integrated with the electronic devices. Textile yarns are an obvious choice and researchers already fabricated conductive cotton fibers with carbon nanotubes (see "Charging your cell phone with your T-shirt").

"However," says Seyed Hamed Aboutalebi, a PhD student at the University of Wollongong's Institute for Superconducting & Electronic Materials,"high-performance multifunctional synthetic fibers produced to date, although of interest from a mechanical and electrical point of view, suffer from low electrochemical performance, which is crucial to the realization of multifunctional textiles required for the advancement of smart electronic devices."

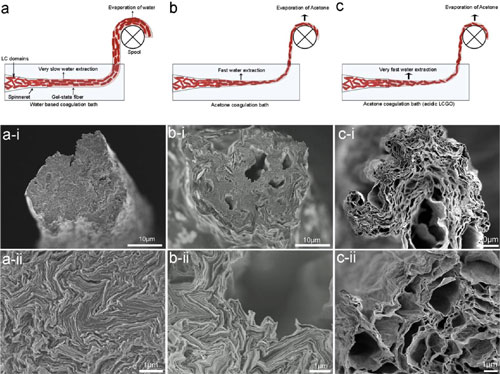

Aboutalebi is first author of a recent paper in ACS Nano ("High-Performance Multifunctional Graphene Yarns: Toward Wearable All-Carbon Energy Storage Textiles") that describes the fabrication of flexible, durable, and self-assembled graphene textile electrodes for supercapacitors using a novel wet-spinning approach of ultra large graphene oxide (GO) liquid crystals followed by heat-treatment to obtain graphene fibers.

These graphene textile electrodes exhibit unrivalled electrochemical capacitance properties of as high as 410 Fg-1 (the theoretical value is 550 Fg-1 whereas the best value achieved to date has been 265 Fg-1).

As the researchers point out, careful, rational nanoarchitectonic design and spacing of individual graphene layers is crucial for high-performance energy storage devices. The key to producing such fibers and yarns is to preserve the large sheet size even after the reduction of GO while simultaneously maintaining a high interlayer spacing in between graphene sheets.

"This in conjunction with maximizing the number of covalently bonded carbon atoms per unit volume or mass and significantly reducing the number of other atoms present at the system and attached to graphene sheets resulted in exceptional electrochemical performance," explains Aboutalebi.

The team's wet-spinning process allows the fabrication of unlimited lengths of highly porous yet mechanically strong (Young’s modulus in excess of 29 GPa), robust and flexible multifunctional fibers and yarns by taking advantage of the intrinsic soft self-assembly behavior of ultra-large graphene oxide liquid crystalline dispersions.

"Both fibers and yarns exhibited outstanding tensile strength and could be easily weaved into conductive textiles, opening up opportunities for the application of graphene in wearable electronic gadgets," Aboutalebi tells Nanowerk.

These graphene yarns could lead the way to the realization of powerful next-generation multifunctional renewable wearable energy storage systems. The simplicity of the method used here and the abundance of graphene oxide precursors make these materials interesting and highly promising candidates for a range of applications such as wearable, light–weight multifunctional textiles and electronic gadgets and flexible energy storage devices to meet the demands of real-world energy storage systems.

Furthermore, the method introduced here along with the team's recent publications – "Graphene oxide dispersions: tuning rheology to enable fabrication" and "Formation and processability of liquid crystalline dispersions of graphene oxide" – can serve as a platform to process these materials at industrially highly-scalable levels for a whole range of both novel and existing applications such as coatings, fillers, molecular electronics, wearables, smart garments, RDIF devices, printed electronics, organic field effective transistors and 3D bionic scaffolds.

Currently, the team is working on the self-assembly process and lyotropic liquid crystallinity as an enabling platform to tailor-make processable self-assembled, self-oriented graphene based hybrids with large-area molecular ordering.

"This will result in the expansion of micro/nanotechnology into areas other than micro/nanoelectronics," says Aboutalebi.

By Michael Berger. Copyright © Nanowerk

Found here http://www.nanowerk.com/spotlight/spotid=34685.php